LADDER SAFETY & LADDER INJURIES

Download PDF of this article here

By Michael Panish, Construction Expert Witness

I am frequently called upon to discuss ladder accidents with attorneys representing workers, contractors, subcontractors, homeowners, and commercial landlords from both plaintiff and defense perspectives.

INJURY CLAIMS AND USER RESPONSIBILITY

There is one basic premise that relates to jobsite safety that needs to be examined closely prior to making an injury claim pertaining to an alleged defective ladder. Every person working with a ladder has the ultimate responsibility prior to climbing onto that ladder to inspect and verify that all parts of the ladder are in good condition. If a proper inspection is made and all visual determinable components appear to be safe for usage, and the ladder fails when used, who is responsible?

On commercial jobsites, OSHA requires that all workers take a personal responsibility for their own ultimate jobsite safety. When working with any jobsite equipment, if a worker feels that the equipment provided to him for a specific job is unsafe, then that worker should inform his supervisor that he cannot safely perform the assigned task. The worker should refuse to perform any job until equipment that is safe and properly functioning is furnished for use. Climbing protection harnesses and lanyards are important pieces of safety equipment that can help workers avoid dangerous fall conditions. Harnesses and safe points of attachment are not part of a ladder, do not attach to most ladders, but need to be considered for all work over 6 feet in height above the ground.

MANUFACTURER’S LABELING

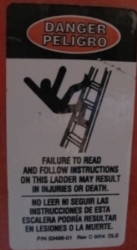

Most ladders from major ladder manufacturers have numerous labels attached to them that indicate a variety of user obligations. Warning labels and usage information are affixed at multiple locations. All ladder users should take the time to thoroughly read and follow those instructions and warnings.

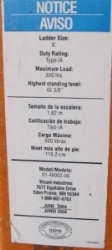

Included among these labels are weight ratings, electrical shock hazard alerts, and how to properly position the ladder for safe usage. Many manufacturers provide informative instructions indicating what components need to be inspected prior to usage, how to use the ladder, and what the maximum height of usage is. Manufacturers of extension ladders affix labels showing what angle of inclination is appropriate for safe climbing.

This label is affixed to the highest safe rung of the ladder telling the user not to stand at or above this level

This label is affixed to the back side of an A Frame ladder

The dangers associated with not following these ladder instructions are clearly outlined on these labels.

Ladder manufacturers provide redundant information to make a user aware of ladder safety.

TYPICAL LADDER MATERIAL

Ladders are manufactured for a wide variety of purposes. Weight load rating requirements depend upon materials that the ladders are made from and design configuration. The three most common commercial ladder materials used are fiberglass, wood, and aluminum.

FIBERGLASS LADDERS

Fiberglass ladders have at least three basic ratings: Medium-duty, heavy-duty, and extra heavy-duty.

Medium-duty fiberglass ladders are usually rated to a maximum of 250 pounds. These ladders are often yellow in color, and sometimes blue depending upon the manufacturer and style of ladder. Weight ratings as listed pertain to the total load of the combined weight of the person and equipment that the ladder can withstand.

Heavy-duty ladders are generally rated to 300 pounds, and Extra heavy-duty ladders are rated to 350 pounds. These two weight designations are often orange in color. Unless otherwise specified and properly configured, most ladders are designed to be used by a single person at a time.

WHAT KIND OF LADDER SHOULD I BUY?

What material is the best choice when buying a ladder?

Wooden Ladders - In the past, wooden ladders were the state of the art. They were subject to failure from exposure to sunlight, moisture, insects, hardware looseness from lack of maintenance or change in humidity, and just the natural weakness of the wood they were built from.

Aluminum Ladders - When aluminum became commonplace for manufacturing, metal ladders were thought to be more durable and safer than previous wooden ladder construction. Aluminum ladders are typically more structurally sound and consistent in strength characteristics than wooden ladders. Aluminum ladder construction eliminated the need for attention to wood shrinkage and expansion that causes loose fitting rungs and struts. One of the most obvious problems with

aluminum ladders is electrical conductivity. Aluminum is an excellent electrical conductor, while wood, unless completely saturated with water, generally is non-conductive.

SHOULD I BUY WOOD OR ALUMINUM?

Purchasers choosing between wood and aluminum ladders need to determine appropriate usage and jobsite requirements that can influence the choice between those two types of products. Weight of the ladders and durability of the ladder structure and hardware are often compared and personal preference for a specific job type would dictate the choice.

Fiberglass Ladders - When fiberglass became available as a ladder choice, contractors gravitated towards the hybrid between the light-weight strength found in aluminum ladders, electrical non-conductivity, and the structural integrity enjoyed with a new wooden ladder. In the early days of fiberglass ladders, they offered strength and ease of movement, but also came with some non-apparent durability issues.

Early fiberglass ladders, when left on roof racks found commonly on contractor’s trucks, were constantly subjected to continual exposure to the sun, wind, and rain in warm climates as well as snow and ice in cold climates. These ladders often experienced delamination of the fiberglass fabric, separation of the hardware components that were drilled into the fiberglass, and ultimate structural failures. Fiberglass was also prone to cracking from resin deficiencies becoming brittle and had problems with structural integrity once the resins broke down.

Today, most fiberglass ladders are considered durable, safe and a good choice. Fiberglass ladders are often more expensive than other ladder material choices. They still require inspection and attention to all of their hardware components prior to usage. Fiberglass ladders should not be left unprotected and exposed to the elements. Fiberglass ladders require vigilance prior to use. All structural components should be thoroughly examined and verified to be tight and securely attached. Fiberglass ladders are susceptible to chemical deterioration. Some paint related chemical products can have catastrophic effects on the resins used to form the fiberglass into a rigid structural element. When fiberglass is exposed to chemical strippers or other solvents the material does not always show outward signs of fatigue. If ladders are borrowed from friends or rented, it is extremely important to make critical inspections and be aware of all past uses that would include detrimental chemicals used on previous jobs.

RENTAL EQUIPMENT

Most times when a customer rents a ladder or any other equipment from a commercial rental company, the renter has no knowledge of the past use or detrimental exposures prior to renting. In many cases the rental company is unaware of how the ladder was used or abused on prior rentals. A rental company has an obligation to investigate renter usage and to take a ladder out of service if questionable usage has occurred. The rental company has an obligation to properly maintain all of their products that are rented.

Appropriate storage, maintenance, and oversight of their rental products is the sole responsibility of the rental company. When a ladder is rented all warning labels and usage information should be clearly visible. Faded and deteriorated or missing warning labels have been the cause of serious injuries to renters. Rental agencies should keep and maintain their ladders under cover, not left out in the open environment exposed to the elements. If a rental company fails to inquire the desired usage from all renters and offer safety related equipment such as harnesses and lanyards when long ladders are rented, the rental company is failing to protect that renter.

Examples of faded and deteriorated labels

Many rental companies insist that protective clothing or other safety devices such as hearing protection and face masks be part of a rental pertaining to products such as jack hammers or other loud equipment. Renting ladders to the general public without instructing or furnishing any OSHA related fall protection safety information is below the standard of care and should be part of any professional rental company protocol.

Many rental companies require renters to take needed safety equipment as part of the rental fees associated with their rental tools, and if returned unused, then the costs associated with that safety gear is refunded upon return. A rental company that has attempted to inform a renter of the potential danger associated with the rented equipment by making safety equipment a part of the rental is meeting the industry standard of care. If the renter chooses not to use the safety systems provided, that user does so at the individuals own risk.

WHY DO NEW LADDERS FAIL?

Brand new ladders can fail due to handling abuse and manufacturing defects prior to your ownership. I have personally returned several fiberglass ladders from home center deliveries that came cracked and damaged even though they were wrapped from the factory. There is no way to know how long, large, or heavy ladders were handled prior to your purchase. New wooden ladders have left the manufacturer, been transported on open trucks, and have arrived with severe cracks and splits in the wooden rails due to changes in climate or simply defective woods that were used to construct the ladders.

It is essential to take the time to completely examine any ladder every time it is used. New, used, or old, ladders can have cracks, breaks or shredded supports with loose strut bracing. Every user should examine any ladder prior to use to determine visible damage before climbing. Failing to do so can lead to serious injuries or death from falling from an unstable ladder that has missing or broken structural components.

STABILITY IS THE KEY TO LADDER SAFETY

For all ladders, it is important to have the base properly positioned prior to climbing. Some ladders have rubberized or metal feet, others hard plastic. Some ladders will slide or “walk” when positioned incorrectly and can shift away from their original position if all feet are not in direct contact with the ground. Many extension ladders feature pivoting metal bases that allow for flat surface footing or when rotated, can point downward into grass or dirt to act as a piercing anchor. The obligation for correct placement and determination of a stable base is the responsibility of the user.

Regardless of the ladder being used, it is important to thoroughly examine all components prior to climbing. Never overreach or exceed the manufacturers load or height requirements. Manufacturers recommend that a person using the ladder keep body position located toward the center of the rungs while using the ladder. Proper maintenance and storage of the ladder when not in use are important to ensure that the ladder is safe for future use.

DEFECTS IN MANUFACTURING

Fiberglass ladders may be affected by improper chemical components that weaken the resins used in their manufacture. Resins that are improperly mixed, missing ultraviolet inhibitors, and improper manufacturing all lead to weak structural fiberglass. Wooden ladders are subject to rot and bug infestations. Dings and dents in an aluminum ladders can structurally affect the ladder integrity due to metal channel deformity. Bent metal components can break when the ladder is loaded down. A ladder that appears perfectly good can spontaneously fail due to some prior abuse or unknown visible defect in the manufacturing process.

TAKE RESPONSIBILITY FOR YOUR PERSONAL SAFETY

Ladder injuries commonly occur. Sometimes they are due to user issues. In order to prevent a fall from a ladder make certain to inspect, evaluate, and positively determine that the ladder is in good condition and properly positioned prior to climbing. In some applications ropes or cabling are essential to ensure that a ladder will not lose its footing or “kick out” as it is climbed. Never use an “A” frame ladder as a substitute for an extension ladder. They are not designed in the same way that an extension ladder is structured and are not always able to withstand the lateral load without four feet placed firmly on the ground. Never use any ladder that is suspicious or partially defective or broken in any way. If it looks weak or previously abused, it is not fit to use.

COMMERCIAL JOBSITE REQUIREMENTS FOR LADDER SAFETY

OSHA (Occupational Safety and Health Administration) requires that personal fall protection be used on commercial jobsites if work is performed over 6 feet above the ground. While fall protection harnesses and lanyards are sometimes considered to be physically restrictive, they have been found to protect people from ladder falls and are OSHA required when working in a commercial environment.

Homeowners are not as well versed in safety protocols as some trade professionals and not required to follow jobsite requirements from OSHA, but reasonable and safe practices should be followed at all times. With any tool, always read and follow the manufacturers warnings and safety procedures. When renting equipment always use a company that provides quality rentals and do not just seek the lowest rental cost. A few pennies could cost you your life.

SUMMARY

Every ladder user is ultimately responsible for their own personal safety. Knowing how to properly inspect and understand the limitations of each type of ladder is important. An exception to this personal obligation is the presence of a hidden deficiency or defective manufactured condition that is not visually apparent.

Workers that rely upon rented ladder equipment should make inquiries as to the previous exposure to any chemicals that could be affecting the structural integrity of the ladder (wood and fiberglass specifically). If the rental ladder is kept outside for long periods of time the structure of the ladder may be compromised. Rental houses and renters should verify that all labels are clear and in readable condition prior to renting.

Do not use the ladder if it has broken or loose components. Over-extension of a ladder, working from rungs that are exceeding the limits of the ladder, or leaning, walking, or jumping with a ladder instead of proper repositioning are dangerous habits and have led to significant fall injuries.

With all equipment, make certain that you have read and understood the manufacturers requirements. Always be aware of potential hazards such as electrical wires, pools of water, soft soils, or automatic gates or equipment that can move into contact with a ladder if they are activated. In some applications, a dedicated person on the ground or barricades should be used to maintain a safe working area under the ladder. This can not only provide safety for the person on the ladder but can protect pedestrians walking by the ladder from falling materials while work is being performed overhead.

Taking a few moments to review the affixed ladder safety information, properly positioning a ladder, and verifying that all components are solid and in good repair can save you from a dangerous fall.

Mike Panish has been providing construction expert witness services since the year 2000. He has been retained on over 2500 legal cases nationwide. He has been the retained expert for both plaintiff and defense cases as well as workmen’s compensation subrogation issues for numerous scaffold and ladder related personal injury and wrongful death cases. He has provided expert opinions on issues of standard of care and job-site responsibility pertaining to all aspects and types of elevated work platforms. If you wish to discuss a pending matter regarding ladder safety or wish more information regarding Mike Panish’s experiences on other cases involving jobsite falls and fall protection do not hesitate to contact his office at 888 902-4272 (ask for Sharon).