AUTOMATIC DOOR SENSORS

The Evolution of Automatic Door Sensors

Download PDF of this article here

By Michael Panish, Automatic Door Expert Witness

Over the past 45 years there have been significant advances in automatic door sensor technologies and greatly improved products introduced into the marketplace. Several major international manufacturers have engineered and designed sensors with many universal applications that have become commonplace in automatic door systems. Many of the major automatic door brands have taken advantage of these ubiquitous sensors and incorporated or at least offered ways to utilize the sensors made by others branded as their own. There are really only 3 major sensor producers that have a significant market share, and these product lines are typically chosen for their superior design, ease of programming and reliability when maintained and aligned correctly.

In the 1970’s, automatic door systems were primarily swing doors, which were installed as the latest advancement for convenience entrances. These systems either replaced or were integrated into existing non-automatic doors. This technology development improved formerly manually operated and often employee attended entry and exit doors. Automated door systems were a definite improvement and seen as more upscale, which increased the customer shopping experiences in a positive way. One of the early swing door manufacturers even referred to its product as if it were “Magic” that the door opened as you approached it. When theme parks began installing automated door systems, they often referred to them as operating “Auto-Magically”. A non-touch, unattended door that opened in front of a customer with a full shopping cart was in fact “Magical” at that time.

Example of pressure sensitive mats used at a market entrance/exit

It all started with pressure sensitive mats

As part of the original design of many automatic door systems, pressure sensitive control mats were used to detect the presence of a pedestrian for both activation and occupation of the door way. These mats typically relied upon electrical circuits, hydraulic or air compression tubing to send signals to the door motor control, causing the doors to open and remain open if the zone was occupied.

These original control mats required testing to verify that the entire mat was active and providing pedestrian recognition. As a result of the need to verify the proper function of the mats, a primitive form of daily safety checks was introduced by door manufacturers and service providers for end users. Essentially, the entity that owned the doorway was responsible for walk testing the control mats each day prior to allowing customers to pass through the door system.

All control mats have known usage-related issues. Today, you will occasionally see the use of control mats with some newer exit doors. I have repeatedly encountered control mats in use coming from restricted access parts of airport terminals into the non-controlled areas of the terminal both in the United States and internationally.

Pressure sensitive mats deteriorate as a result of environmental conditions. Most mats were/are made from some type of rubber or vinyl with integrated electrical circuits, hydraulic or pneumatic closed systems. As a result of sun, sand, heat, snow, ice, chemicals, or even expected customer impacts from normal walking or rolling carts over them, the mats can become unreliable and do not continue to open or hold open the doors when a pedestrian occupies the area. They are less reliable and less durable outdoors, so most newer control mats are mainly used indoors where they are not exposed to weather.

Touchless technology becomes part of automatic door systems

Primitive control mat activation and presence detection worked until more reliable technology was available in the form of overhead sensors. Alternative products were sought to replace the pressure sensitive mats, and that is where the early infrared or microwave sensors came into this industry. It is interesting to note that current industry standards for daily testing still refer to mats as part of the possible activation devices that need to be tested and evaluated on a daily basis, despite their relatively rare use in modern systems.

Early overhead approach sensor

With the development of motion detection sensors for public use, some older swing doors with mat sensors had their activators disabled. Some installations combined these mats with a motion detecting sensor that used a type of doppler reflection or infrared detection. These primitive sensors were an improvement over a defectively operating control mat but did not ensure complete pedestrian safety due to their limited view of the doorway. As these new motion detecting sensors were incorporated into door systems, the existing floor control mats were primarily used for presence detection.

Early types of motion detecting sensors had problems with color saturation that failed to consistently detect a pedestrian. For instance, if the carpets under or near the doorway were gray or black, and a person walked through the opening wearing dark clothes, the sensor might not discern the difference between the flooring and the pedestrian and not hold the door or even open up the door. That is why many early attempts to use overhead sensors were combined with the floor control mats, and then later used in conjunction with door belt loop sensors and various other door mounted sensors.

The early activation sensors were mounted overhead of the doors and provided a signal to make the doors open. They typically did not possess any presence detection once a pedestrian had passed under their zone of coverage. Swing doors often used a timer to hold the door open, and that would hold the door open as long as the preset timer was counting down. The problem with a timer holding the door open is that a slow moving patron may linger in the doorway and exceed the preset timer, which would lead to an impact injury.

Another sensor combination involved using a floor control mat to detect the presence of a pedestrian in the door swing path. However, if a partially functional control mat used to detect pedestrian presence did not recognize a pedestrian obstruction, the doors would close. Over time, combinations of various sensor products were used with varying degrees of safety. In older installations, it is still possible to see antiquated sensor configurations that may or may not be connected but were not removed when sensors were upgraded.

Swing door with older style presence detecting door mounted device

Common older sliding door sensor configurations included the black motion detection sensor (BEA EAGLE) and the horizontal silver with black ends presence detection sensor commonly referred to as a “Stanguard”.

When sliding door systems were originally put into the marketplace, control mats and electric eye holding beams were the standard issue from many manufacturers. Later, as overhead sensor systems became available, the control mats were replaced with a motion detection sensor on each side of the door, and a single threshold protecting overhead sensor to determine if the path of travel had pedestrian presence. Some of these threshold protecting sensors had multiple emitters that “rained down” beams over the width of the threshold. These early presence detectors often would have 3 to 5 emitter locations needed to fully cover the width of the doorway. Sometimes one or more of the emitters would not be functional so complete coverage of the door threshold was not possible. These sensors came with a change to the door inspection daily testing. It was now required to approach the door, see that the door opened when you were about 4 feet in front of it, walk upon the threshold, stand motionless for 10 seconds on the threshold, and then walk through the opening and repeat the process from the opposite direction. There was also an independent test for the cross threshold holding beams to see if they were active.

A single cross threshold optical holding beam

As time went on, industry standards changed and the requirement for tighter threshold protection increased. At one point in time, it was acceptable for threshold protection to be active within 5 inches of the door face, and that was later amended to be within 3 inches. Hold open times for threshold protection also changed from the original 10 seconds of occupancy to 30 seconds where the door must not move to close. As these standards evolved, more and different types of sensors were used to accomplish and meet the revised standards of pedestrian protection. The daily walk tests became more substantial and involved a greater degree of inspections to ensure pedestrian safety.

Various common combination approach and presence detecting sensors

Fortunately, sensors continued to evolve, and more and more features were incorporated into single devices. The overhead door sensors changed to include both motion and presence detection functions within a single unit. In many installations, the advanced technology of the combination sensors eliminated the need for cross threshold holding beams. As sensor technology and design developed, a “look back” ability was incorporated into the functions. This meant that if the sensor was appropriately positioned, the sensor could be mechanically adjusted so that it could actually look behind through an open doorway, see what was on the opposite side of the door, and be adjusted so that it would cover the doorway closer than the revised standard of 3 inches to the face of the door. Of course, over adjustment of sensor sensitivity of this kind of sensor would actually hinder the door functions because the sensor would continually observe the moving door as it closed and see it as an obstruction causing a reopening of the door endlessly.

In the earlier iterations of door combination sensors, adjustments were acceptable but had some limitations in automatic door systems. Remember that the sensor manufacturers make their sensors for a wide variety of potential applications, and not all of the possible adjustments apply to automatic door operations.

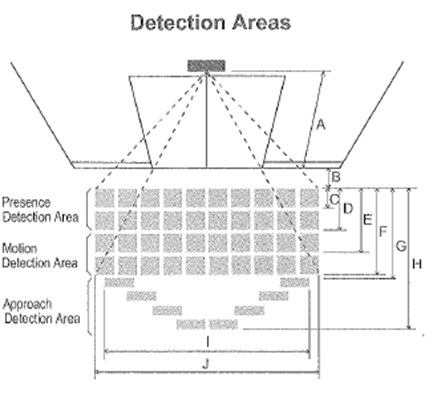

A pictorial illustration as an example of potential adjustment possibilities with more recent combination sensors placed on each side of the doorway.

Later and more recent sensor designs have incorporated pixilated adjustment possibilities. Imagine stadium seating or anemone arms to visualize how advanced sensors can be precisely tuned. There are sections of rows that can be adjusted in these devices that detect motion, transition to both motion, and presence detection, and then can be turned both left and right, forward and backward and cover most installation peculiarities. The current requirement for sensor functions for automatic door systems is to provide approach coverage approximately 43 inches in front of the door face for the full width of the doorway. Transition with full and complete overlapping coverage to the presence detector portion of the sensor. Provide monitoring of the threshold for a minimum of 30 seconds to detect even a motionless pedestrian standing upon the threshold and then protect the opening until the opposite sensor picks up the pedestrian passing through the opening until out of the zones of coverage. As seen in the photo below, it is not unusual to have older technology sensors (lower sensor) left in position, when modern, current technology sensors(upper sensor) are installed as an upgrade. Sometimes both sensors are left functional, other times they are removed or left in original locations.

Example of a door system that has a modern version of a combination motion/presence detecting sensor (upper sensor) over an older technology presence detection sensor that is now disconnected (bottom horizontal sensor)

As of June, 2017, all new door systems were required to self monitor and verify sensor and door operations to be standard compliant. There is no requirement to upgrade earlier door systems. There is still a requirement for daily safety inspections, but it was the desire of the standard to add another layer of pedestrian safety where a system could determine for itself whether there was adequate and functional sensor protection or disable the door system until it could be repaired. Not all of the post June, 2017 systems are fool proof, and that is why the human must still observe and test the doors as before.

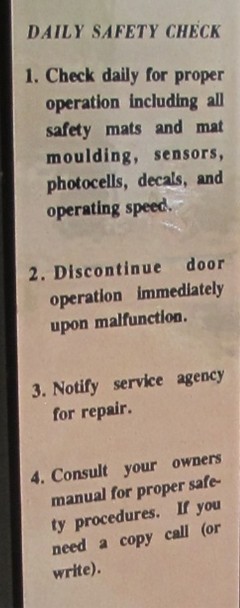

Commonly used daily safety check stickers

Part of the ongoing responsibility of all automatic door owners, past and present, is the obligation to seek professional service providers at least on an annual basis. For high traffic installations, quarterly inspections of automatic doors are recommended. Unfortunately, some store owners opt not to pay for proper inspections and instead monitor the doors in ways that may result in pedestrian injuries.

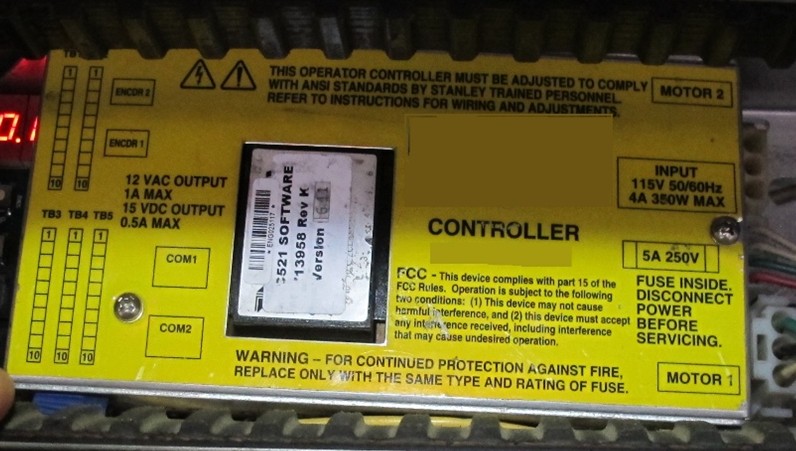

Example of a common motor control module

As sensors improved and new technologies developed, automatic door sensors became more reliable, but not all of the other door components that the sensors communicate with improved as quickly. There are motor controllers that every experienced door installer or technician has encountered in many automatic door systems. Some of these controllers have had many years of inconsistency that have created undiagnosed issues that have led to pedestrian injuries. These motor controllers accept and poll the output signals of all of the door sensors, and then determine that there either is, or is not an obstruction, and allows the motor to initiate door closing. Some of these inconsistent controllers have been replaced or received improved software upgrades but many remain in use as part of older door systems.

Compare Automatic Door Systems to Human Anatomy

Understanding how sensors and automatic controllers operate can be confusing. One of the simplest ways to explain component functional characteristics of automatic door systems is to offer the following comparisons between human body parts and the various similarly functioning components found on many automatic door systems.

Here is where it is important to understand how sensors integrate into a door control module. We can compare all door sensors and other automatic door components with human anatomy. In very basic terms, sensors on door systems are like human eyes.

They see what they are focused upon and then transmit the acquired input through control cables that are equivalent to the optic nerve in a human. The optic nerve in a person conveys the sensory information that the eye has gathered to the receptors in the brain. Similarly, the sensor output cable sends information to the motor control module in an automatic door system.

The controller is the equivalent of a human brain in its job. The brain of a person then interprets the stimulus and acts accordingly allowing understanding of the eye output or confusion due to a potential variety of scrambled signals or damaged eye elements.

A person can have fully functional eyes but have a damaged optic nerve or damaged nerve receptors in the brain and be unable to see or be partially blind. A person can have damaged eyes that do not pick up sensory inputs, yet a fully functional optic nerve that is able to transmit information to the brain receptors, and still be unable to see, or have sustained damage to the brain receptors with fully functional eyes and optic nerve and remain blind.

Automatic door systems that rely upon sensors to determine whether the door needs to open, stay open or close can encounter various issues with their components. Sensors may be operational but misaligned, failing to monitor the necessary areas. They could also be partially functional, and missing critical areas of coverage, or they could be completely defective and not sending any signals to the door controller. The sensor output cable might be fully functional, intermittently functional, or not functional due to broken connections or disconnected input terminals on the control module. The control module itself may have missing file information due to corrupted software that cannot interpret the incoming signals of the fully functional sensors, can misinterpret the signals and cause errant door operations. Additionally, electrical noise can interfere with signal transmission, causing inappropriate reactions such as impacts with pedestrians or inconsistent door opening and closing.

Hopefully, the above explanations clarified the similarities of function in human vs automatic door terms. Understanding these interactions can help you see why door injuries happen and how proactive steps can prevent automatic door injuries.

The automatic door industry expects that all automatic door end users perform daily safety checks whenever the door is first powered on, each and every day, or whenever there is a power outage. There are typically stickers placed adjacent to the door switch controls that warn and describe information about how to inspect and verify safe operations of the door prior to allowing the door to be used by any pedestrian, whether employee or patron.

Failing to perform daily safety inspections may result in not identifying any defective operations of the door system before usage. When performed correctly, along with annual or quarterly inspections by a professional service provider, the door owner meets their standard of care, and it is likely that the door will operate in a reasonably safe condition.

This article is intended to enhance your understanding of automatic door sensors, the operation of components within generic automatic door systems and how they have changed over the past 45 years. However, it is not intended to serve as a comprehensive or exhaustive training manual for such systems. There are many other components and functional adjustments required to make an automatic door system standard compliant and safely functioning.

Mike Panish is the nation's leading automatic door expert, having been retained on over 2500 cases since 2000 in all 50 States and Canada. Mike Panish is internationally recognized for his expertise, and he is frequently retained by multinational companies and service providers in defense of claim. Mike has been involved with automated door systems of every kind since the mid 1970’s and continues to provide his expertise for both plaintiff and defense. This article is just a sample of the depth of industry information that he has developed during a lifetime career.

Mike Panish has provided courtroom testimony for all types of door and gate access systems, helping to accomplish multimillion dollar verdicts for plaintiffs and zero defense verdicts for the defendants. He provides unbiased testimony based on over 45 years of actual trade experiences working with door systems of every kind.

You can learn more about Mike Panish’s expert witness services by visiting www.ConstructionWitness.com or call (888) 902-4272.